- Program

- Värme och kyla

Consortium materials technology for thermal energy processes, KME – reporting completed

KME focused on developing material technology to create maximum efficiency for energy conversion of renewable fuels and waste. KME had its sights firmly set on continuing to raise the efficiency of long-term sustainable energy as well as ensuring international industrial competitiveness.

Because the challenge of implementing environmentally sustainable energy was both complex and vital, the KME consortium is financed by the Swedish Energy Agency together with stakeholders from the energy industry, manufacturers of systems and components for energy conversion and material producers.

The programme was operated and managed by Energiforsk. During the programme period of 2018 and 2022, five industry-relevant projects were conducted. The projects covered a wide range of research areas, such as the mechanical behaviour and corrosion of various materials in different high-temperature environments, as well as the performance of different coating materials.

The Swedish translation of KME: Konsortium Materialteknik för Termiska Energiprocesser.

Bertil Wahlund

Programansvarig Värme och kyla, Energisystem och Vattenkraft

Programansvarig Värme och kyla, Energisystem och Vattenkraft

Partners

Babcock & Wilcox Vølund A/S

Calderys

Höganäs

MH Engineering

Sumitomo SHI FW Energia Oy

Valmet Technologies Oy

Energy companies participating via Energiforsk

Falu Energi & Vatten

Jämtkraft

Karlstads Energi

Kraftringen

Mälarenergi

Stockholm Exergi

Tekniska verken i Linköping

Vattenfall

Ørsted Bioenergy and Thermal Power A/S

Universities and institutes

Chalmers University of Technology

University West

Linköping University

Rise Kimab

Rise IVF

Rapporter och publikationer

Här listas rapporter och resultatblad från programmet.

- Rapport

Increased flexibility and power production from biomass 2023-932

Det övergripande syftet med projektet var att öka effektiviteten och förutsägbarheten/flexibiliteten i el/värmeproduktion från biobränslen. För att uppnå målet användes två strategier: materialutveckling och oxidationstillväxtssimulering.

|2023:932Johan Eklund, John Hald, Richard Shen, Søren Aakjær Jensen, Hanna Kinnunen, Maria Dolores Paz Olausson, Laura Rioja-Monllor, Vicent Ssenteza, Torbjörn Jonsson and Bertil Wahlund

- Rapport

New materials for improved Competitiveness of fb plants using Renewable fuels

För att öka andelen förnybara bränslen, på bekostnad av fossila bränslen, måste konkurrenskraften öka för kraftverk och kraftvärmeverk som använder förnybara bränslen.

|2023:931Hampus Lindmark, Fredrik Lind, Jesper Liske, Maria Dolores Paz, Laura Rioja-Monllor, Bertil Wahlund, Anna Jonasson, Johanna Nockert, Matti Hautakangas, Hans Larsson, Kyösti Vänskä & Vesna Barisic

- Rapport

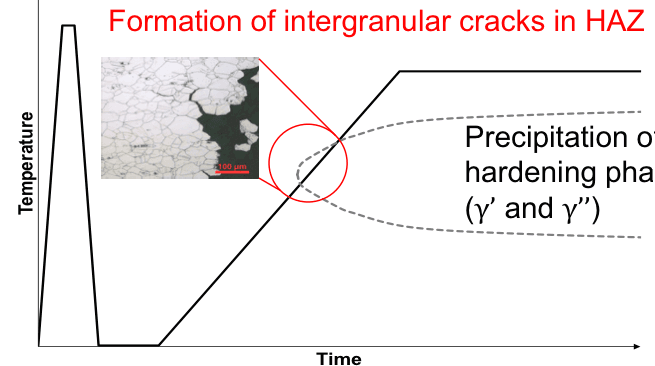

Heavy section austenitic stainless steel For headers and piping in high-efficient Biomass-fired power plants

Idag används ferritisk stål i tjockväggiga komponenter i högeffektiva biomasseldade kraftverk, men de är inte tillräckliga. Tjockväggiga AASS skulle kunna ersätta den ferritiska stålen- men det krävs fler undersökningar.

|2023:930 Mattias Calmunger, Guocai Chai, Maria Sundqvist, Vesna Barišić, Kyösti Vänskä, Bertil Wahlund, Mikael Segersäll, Johan Moverare Och Hugo Wärner

- Rapport

Increased Fuel Flexibility And Performance For Boilers With Challenging Fuels

Projektet KME-802 "Ökad bränsleflexibilitet och driftprestanda för pannor med utmanande bränslen" har syftat till att förstå vilka materialutmaningar som är de mest kritiska för pannors driftprestanda.

|2023:928 Alice Moya Núñez, Melina da Silva, Rikard Norling, Thomas Höjer, Anna Jonasson, Peter Gewert