Projektdeltagare

Fredrik Engström, LTU/Vattenfall

Publiceringar

A. Soltani Dehkharqani, F. Engström, J.-O. Aidanpää, and M. Cervantes, ‘An Indirect Measurement Methodology to Identify Load Fluctuations on Axial Turbine Runner Blades’, Sensors, vol. 20, no. 24, 2020.

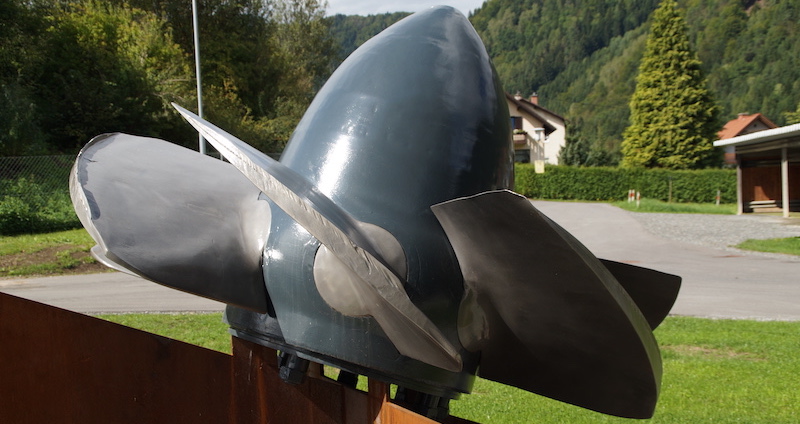

A. Soltani Dehkharqani, F. Engström, J.-O. Aidanpää, and M. Cervantes, ‘Experimental Investigation of a 10 MW Prototype Axial Turbine Runner : Vortex Rope Formation and Mitigation’, Journal of Fluids Engineering, vol. 142, no. 10, 2020.

A. Soltani Dehkharqani, F. Engström, J.-O. Aidanpää, and M. Cervantes, ‘Experimental Investigation of a 10 MW Prototype Kaplan Turbine during Start-Up Operation’, Energies, vol. 12, no. 23, 2019.

A. Soltani Dehkharqani, J.-O. Aidanpää, F. Engström, and M. Cervantes, ‘A Review of Available Methods for the Assessment of Fluid Added Mass, Damping, and Stiffness With an Emphasis on Hydraulic Turbines’, Applied Mechanics Review, vol. 70, no. 5, 2018.

A. Soltani Dehkharqani, J.-O. Aidanpää, F. Engström, and M. Cervantes, ‘Fluid added polar inertia and damping for the torsional vibration of a Kaplan turbine model runner considering multiple perturbations’, in IOP Conference Series : Earth and Environmental Science, 2019, vol. 240.

M. Cervantes and A. Soltani Dehkharqani, ‘Prototype Kaplan turbine measurements : Instrumentation overview’, presented at the 2nd IAHR-Asia Symposium on Hydraulic Machinery and Systems, Busan, Korea, September 24-25, 2019, 2019.

A. Soltani Dehkharqani, ‘An Experimental Investigation of a Prototype Kaplan Turbine and Numerical Analysis of Fluid Added Parameters on the Corresponding Model Turbine Runner’, PhD dissertation, Luleå tekniska universitet, Luleå, 2020.

Soltani Dehkharqani and M. Cervantes, ‘Experimental investigation of a prototype Kaplan turbine runner’, presented at the 15th Asian International Conference on Fluid Machinery (25th - 27th September 2019, Busan, Korea), 2019.