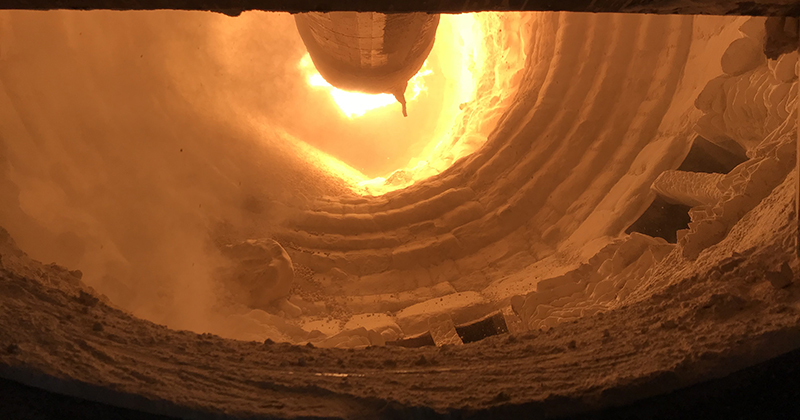

In this study, the heating rate as main parameter has been investigated with its relation to particle strength and size distribution. Four different lime samples were tested; three ordinary lime muds and one lime sample from the electrostatic precipitator.

Carbon dioxide affected the degree of calcination negatively but had only a small impact on the particle size distribution. It was a tendency that a higher heating rate gave more particles in the smaller size fractions which might increase the severity of lime kiln dusting as heat is transferred further back in the oven with the sensible heat of the dust particles and thereby increase the heating rate.